One of the most well known styles of wheat beer is German weizen, but that’s not the only kind there is. Unlike weizen, American-style wheat beer uses a relatively clean fermenting American ale yeast instead of the banana/clove German weizen yeast. It may be a case of personal preference, but the American wheat beer recipe offers a wheaty flavor without the phenolic overtones.

One of the most well known styles of wheat beer is German weizen, but that’s not the only kind there is. Unlike weizen, American-style wheat beer uses a relatively clean fermenting American ale yeast instead of the banana/clove German weizen yeast. It may be a case of personal preference, but the American wheat beer recipe offers a wheaty flavor without the phenolic overtones.

American wheat beer is a great beer for summer, typically light in color and light to medium-bodied. While hop bitterness and flavor are certainly present in this style, they’re generally not the main feature in American wheat beer. The American ale yeast tends to be somewhat neutral, but may present some mild fruity characteristics. Popular examples of American wheat beer include Boulevard Unfiltered Wheat and Goose Island 312 Urban Wheat Ale.

The BJCP Style Guidelines for an American wheat beer recipe call for the following specs:

- OG: 1.040 – 1.055

- FG: 1.008 – 1.013

- IBU: 15 – 30

- SRM: 3 – 6

- ABV: 4 – 5.5%

When brewing an all-grain American wheat beer, rice hulls are recommended to help avoid a stuck mash. John Palmer recommends rinsing the rice hulls before use.

The American wheat beer recipe below makes a fairly straightforward beer. Sparge with hot water (possibly hotter than normal) to help avoid a stuck sparge. If you’re a fan of hops flavor and aroma, consider adding some hops additions later in the boil.

Good luck!

American Wheat II, from Brew Your Own magazine

(5-gallon batch, all-grain recipe)

Specs

OG = 1.051

FG = 1.012

ABV = 5.1%

IBU = 21

SRM = 3.5

Ingredients

5.8 lbs. malted wheat

4.6 lbs. two-row brewer’s malt

8 oz. rice hulls

1 oz. Cascade hops at :60

Wyeast 1010: American Wheat Beer yeast

Directions

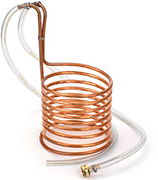

The day before brewing, prepare a 2L yeast starter from one packet of liquid yeast, or plan on using two packets. Mash crushed grains at 150˚F for 60 minutes. Sparge with hot (~190˚F) water to collect 5.75 gallons of wort. Boil for 60 minutes, adding one ounce of Cascade hops at the beginning of the boil. At end of boil, cool wort to 70˚F or below and transfer to a clean, sanitized fermenter. Ferment at 70˚F. Bottle or keg and carbonate to 2.3-2.5 vols CO2.

Easy Extract Option: Replace the malted wheat and two-row malt with 7.3 lbs. of Wheat LME and omit the rice hulls.

Looking for an American wheat beer recipe kit? Try the Steam Freak: Amber Waves American Wheat Beer kit!

———————————————————————————————————–

David Ackley is a beer writer, brewer, and self-described “craft beer crusader.” He holds a General Certificate in Brewing from the Institute of Brewing and Distilling and is founder and editor of the Local Beer Blog.

As I’ve mentioned before, my significant other has a gluten allergy. She actually cried when she called to tell me the diagnosis, upset that we wouldn’t be able to share beer experiences anymore. Fear not, I told her. We’ll find a way.

As I’ve mentioned before, my significant other has a gluten allergy. She actually cried when she called to tell me the diagnosis, upset that we wouldn’t be able to share beer experiences anymore. Fear not, I told her. We’ll find a way.

The Beer Judge Certification Program lists 23 different categories of beer styles, most of which have two or more subcategories. Almost every category name is fairly descriptive, but the last one stands out as rather broad. What is a “Specialty Beer”?

The Beer Judge Certification Program lists 23 different categories of beer styles, most of which have two or more subcategories. Almost every category name is fairly descriptive, but the last one stands out as rather broad. What is a “Specialty Beer”? Experience is key. Network, volunteer, get some education. Take biz classes too. Check out Sam Adams program. Get financed.

Experience is key. Network, volunteer, get some education. Take biz classes too. Check out Sam Adams program. Get financed. The heat of summer, the sting of sweat in your eye, the smell of fresh cut grass. After mowing the lawn, everyone needs a good “lawnmower beer” to cool down! The perfect remedy: an American cream ale.

The heat of summer, the sting of sweat in your eye, the smell of fresh cut grass. After mowing the lawn, everyone needs a good “lawnmower beer” to cool down! The perfect remedy: an American cream ale. As homebrewers, we spend lots of time thinking about all the ingredients that we put into our beer. But what about the things that come out of our brew day?

As homebrewers, we spend lots of time thinking about all the ingredients that we put into our beer. But what about the things that come out of our brew day? The Beer Judge Certification Program classifies six kinds of stout:

The Beer Judge Certification Program classifies six kinds of stout:  While malt is responsible for fermentable sugars and flavor,

While malt is responsible for fermentable sugars and flavor,

Fermentation chamber – A dedicated fermentation chamber is the best way to control the temperature of your homebrew fermentations. Search craigslist or your local classifieds for a used refrigerator or freezer. You can even modify it into a kegerator with a

Fermentation chamber – A dedicated fermentation chamber is the best way to control the temperature of your homebrew fermentations. Search craigslist or your local classifieds for a used refrigerator or freezer. You can even modify it into a kegerator with a