Hi everyone!

Hi everyone!Bottling day for the mead is (finally) here! I’ve been through quite a lot with this wine. I think I ended up racking it at least 3 times to not much avail, then finally figured out that I might be dealing with a stuck fermentation and added the appropriate ingredients to get that going again (yeast nutrient and yeast energizer). That seemed to do the trick to clear things up, even though the specific gravity barely changed (if at all).

I made the executive decision to move forward and filtered the wine for my first time ever. As luck would have it, I ran into some troubles there as well, which were 100% human error (how about reading the instructions out loud….that might help).

We’re finally at bottling day! We’re down to the wire—about to get married, go on a honeymoon, then possibly move into a new house somewhere (who knows where at this point). The time to bottle the wine is now, and there is no other way about it!

So, I rinsed all the bottles I’d been saving in very hot water (I had been sure to rinse them out immediately after emptying them so there wouldn’t be any foreign bodies growing in there), then added a couple turkey baster sized squirts of sanitation liquid to kill anything that might be still living in there. All went well—no problems there (that I am aware of).

So, I rinsed all the bottles I’d been saving in very hot water (I had been sure to rinse them out immediately after emptying them so there wouldn’t be any foreign bodies growing in there), then added a couple turkey baster sized squirts of sanitation liquid to kill anything that might be still living in there. All went well—no problems there (that I am aware of).I ended up with exactly 24 bottles of wine, with the last few being dubbed “the dregs”. I think this entire batch will be consumed by both my fiancé and I, as I’m not proud of it enough to give it to anyone else.

After bottling, I noticed that the wine was still a little hazy. I’m not surprised, since I only really partially filtered the wine during my first attempt. I did have enough filter pads to do it again, but I figured I would just learn from my mistake, move on, and save the pads for my next batch of wine that I hopefully won’t mess up so much!

I’m happy that the mead is done. It’ll probably be a nice “second bottle of the night”. Perhaps I’ll pair it with some cheese if it’s too awful to have by itself. Ha! All I have to say now is I am glad that space the carboy was taking up is now clear—any table space is prime real estate these days.

——————————————————————————————————————–

My name is Leigh Erwin, and I am a brand-spankin’ new home winemaker! E. C. Kraus has asked me to share with you my journey from a first-time dabbler to an accomplished home winemaker. From time to time I’ll be checking in with this blog and reporting my experience with you: the good, bad — and the ugly.

My name is Leigh Erwin, and I am a brand-spankin’ new home winemaker! E. C. Kraus has asked me to share with you my journey from a first-time dabbler to an accomplished home winemaker. From time to time I’ll be checking in with this blog and reporting my experience with you: the good, bad — and the ugly.

A friend gave me a bottle of homemade wine and the top of the cork is green and fuzzy. Is it still safe to drink?

A friend gave me a bottle of homemade wine and the top of the cork is green and fuzzy. Is it still safe to drink?

I recently had the opportunity to judge at a local homebrew competition.

I recently had the opportunity to judge at a local homebrew competition.

Last week I put together a

Last week I put together a

Dave Juliano shares how to convert a refrigerator to a fermentation chamber without losing the freezer function.

Dave Juliano shares how to convert a refrigerator to a fermentation chamber without losing the freezer function.

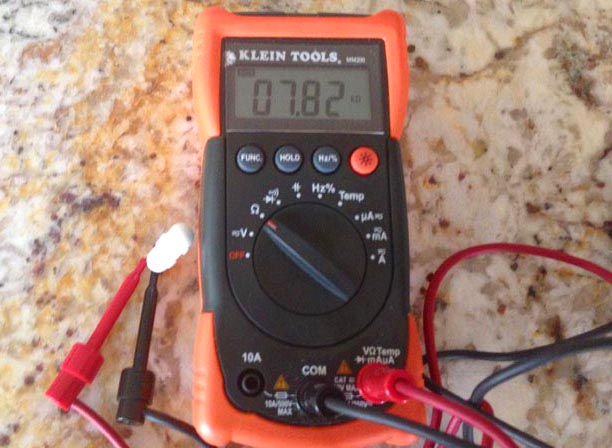

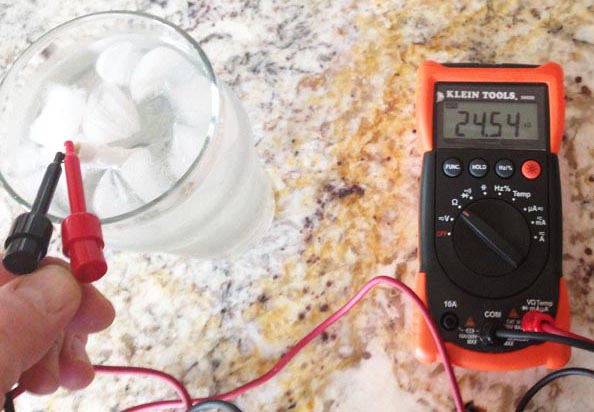

Using the multimeter set to read resistance (Ohms), connect the leads to each wire from the thermistor at room temperature.Here, mine is reading 7.82K Ohms at about 78°F. The temperature isn’t important – we just want to know that what the fridge computer reads from the thermistor is two states – hot and cold. Hot is any temperature above where we want to be. I brew ales and plan to lager, and saw no reason to ferment higher than this. If you’re doing something different, adjust the ambient temperature of this step accordingly!From this information, I know that when the fridge computer reads 7.82K Ohms, it will want to turn on to cool the fridge down.

Using the multimeter set to read resistance (Ohms), connect the leads to each wire from the thermistor at room temperature.Here, mine is reading 7.82K Ohms at about 78°F. The temperature isn’t important – we just want to know that what the fridge computer reads from the thermistor is two states – hot and cold. Hot is any temperature above where we want to be. I brew ales and plan to lager, and saw no reason to ferment higher than this. If you’re doing something different, adjust the ambient temperature of this step accordingly!From this information, I know that when the fridge computer reads 7.82K Ohms, it will want to turn on to cool the fridge down. Keeping the multimeter set and the thermistor connected, now place the thermistor in a glass of ice water. This is 32°F, and represents the “cold” side of my needs. When the fridge computer reads 24.54K ohms, I know it will turn off.

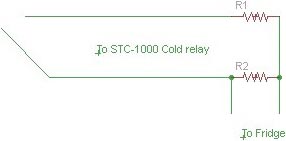

Keeping the multimeter set and the thermistor connected, now place the thermistor in a glass of ice water. This is 32°F, and represents the “cold” side of my needs. When the fridge computer reads 24.54K ohms, I know it will turn off. The STC-1000 will close the relay when the external probe reads a temperature above the set point, so when that relay closes, we want the fridge computer to read <8K ohms. When the temperature falls below the set point, the relay opens, so we want the fridge computer to read >24K ohmsI designed this simple schematic so that the fridge computer was reading R2 directly, and when the relay closed, R1 would be added to R2 in parallel, dropping the resistance read by the fridge, telling it to start to cool.

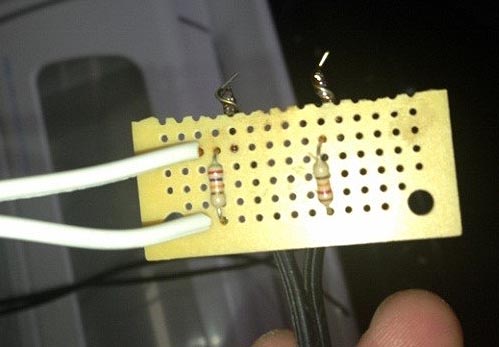

The STC-1000 will close the relay when the external probe reads a temperature above the set point, so when that relay closes, we want the fridge computer to read <8K ohms. When the temperature falls below the set point, the relay opens, so we want the fridge computer to read >24K ohmsI designed this simple schematic so that the fridge computer was reading R2 directly, and when the relay closed, R1 would be added to R2 in parallel, dropping the resistance read by the fridge, telling it to start to cool. Assemble the perfboard. I soldered the two resistors to the perfboard, using their leads to make the connections, and also two pigtails of braided wire. The white wire was cut off of the end of the old thermistor, and the black is just some speaker wire I had that will connect to the temperature controller relay. Follow the schematic from above to ensure you have it wired correctly.

Assemble the perfboard. I soldered the two resistors to the perfboard, using their leads to make the connections, and also two pigtails of braided wire. The white wire was cut off of the end of the old thermistor, and the black is just some speaker wire I had that will connect to the temperature controller relay. Follow the schematic from above to ensure you have it wired correctly. Wire it in: the white wires got crimped back in to where the thermistor was removed. The black wires got crimped onto the wires coming from the “Cold” relay on the STC-1000. Neither of these connections has a polarity to worry about. I had previously drilled a hole in the top of my fridge case by first making sure no refrigerant lines were in the way (check YouTube for lots of great videos on how to do this!).

Wire it in: the white wires got crimped back in to where the thermistor was removed. The black wires got crimped onto the wires coming from the “Cold” relay on the STC-1000. Neither of these connections has a polarity to worry about. I had previously drilled a hole in the top of my fridge case by first making sure no refrigerant lines were in the way (check YouTube for lots of great videos on how to do this!). I tucked the bit of board and the wire into the shroud that holds the fridge electronics, and reinstalled the panels and covers. I did have to drill a small hole in the plastic shroud to allow the black wire from the temp controller out.

I tucked the bit of board and the wire into the shroud that holds the fridge electronics, and reinstalled the panels and covers. I did have to drill a small hole in the plastic shroud to allow the black wire from the temp controller out. With everything plugged in and cooling, the STC-1000 is now in control of the fridge, while the factory-provided temperature circuitry was still in control of the freezer, and I could watch the temperature drop in the fridge! (Remember, this is Celsius, and in my garage in Tucson)

With everything plugged in and cooling, the STC-1000 is now in control of the fridge, while the factory-provided temperature circuitry was still in control of the freezer, and I could watch the temperature drop in the fridge! (Remember, this is Celsius, and in my garage in Tucson)

Ed, I was looking for answers for when a malo-lactic fermentation is completed and

Ed, I was looking for answers for when a malo-lactic fermentation is completed and

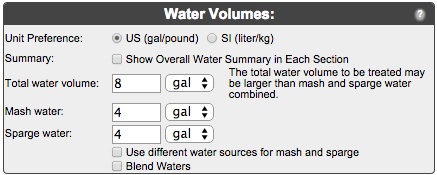

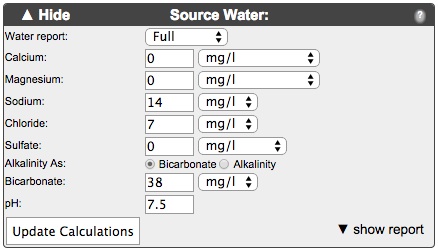

There are all sorts of different ways to start homebrewing – various setups, recipes and equipment to use.

There are all sorts of different ways to start homebrewing – various setups, recipes and equipment to use.

Well I have some good news to report in that my mead finally cleared up! Actually, it was rather amazing how quickly it cleared up after I added

Well I have some good news to report in that my mead finally cleared up! Actually, it was rather amazing how quickly it cleared up after I added