Hi all!

Hi all!

Ah the drama of finding a new home never ends! We haven’t moved yet, but we’re oh so close!

That being said, I’m still in a holding pattern when it comes to my home winemaking. I thought I would take time today to figure out my next steps in terms of what wine I would like to make next, and what equipment I should get based on what I have already and what I feel would be really beneficial for me to have based on my experiences so far with home winemaking.

I’ve only made one red wine so far (recall: the Carmenere). This one actually came out pretty well, and we actually served some of it at our wedding (and people liked it!!). So far, it’s been my favorite of my homemade wines, so I think I’ll try my hand at another red to see what happens!

I’ll probably do another wine ingredient kit this time, rather than purchasing separate ingredients. It’s just easier that way, and while we’re settling into our new house (wherever that may be), it’ll just be more straightforward and simple.

In addition to the wine ingredient kit, there are a few pieces of equipment I would like to get, partially to help monitor my wines more closely as the process moves along, and also partially to start building up my own mini home winemaking empire (in my dreams, right?).

First of all, I really need a digital pH meter. I did buy that acid test kit, which will come in very handy, but I think having a pH meter will be equally, if not more, telling when I’m testing my wine for acid levels. I think more information is always better, so it wouldn’t hurt to have both. Besides, if I decide to make mead again, the acid test kit I bought is pretty much useless anyway, so I’ll definitely want the pH meter at that point.

If I’m going to be starting my wine from fruit in the near future, I’ll probably want a scale in the house as well. I suppose having a scale would be useful in the kitchen in general, so it’s really a solid investment. I like the look of the Escali:Mercado Dial Scale that I spotted on the ECKraus website, as it measures just about anything (grains,fruits, sugar, etc) and is affordable at just under $40.

Finally, one day I’d like to get a stainless steel fermenter. I’ll definitely want to be making wine on a more regular basis in order to convince my husband to let me get one of these, but I don’t particularly care for the plastic fermenter and would like to upgrade eventually.

All these things will come in due time, but for now I am going to focus on my next wine ingredient kit.

————————————————————

My name is Leigh Erwin, and I am a brand-spankin’ new home winemaker! E. C. Kraus has asked me to share with you my journey from a first-time dabbler to an accomplished home winemaker. From time to time I’ll be checking in with this blog and reporting my experience with you: the good, bad — and the ugly.

My name is Leigh Erwin, and I am a brand-spankin’ new home winemaker! E. C. Kraus has asked me to share with you my journey from a first-time dabbler to an accomplished home winemaker. From time to time I’ll be checking in with this blog and reporting my experience with you: the good, bad — and the ugly.

We would like to stop and take a moment to wish you the very best this holiday season. We sincerely hope that your Christmas is full of joy and excitement, and that the New Year brings you the brightest of days and provides you with all for which you strive.

We would like to stop and take a moment to wish you the very best this holiday season. We sincerely hope that your Christmas is full of joy and excitement, and that the New Year brings you the brightest of days and provides you with all for which you strive. After

After

Hi guys! Leigh here!

Hi guys! Leigh here!

Hello readers! Leigh here! I’m back from my wedding/honeymoon adventures!

Hello readers! Leigh here! I’m back from my wedding/honeymoon adventures!

In the afternoon session of my recent BJCP beer judging experience, I was assigned to

In the afternoon session of my recent BJCP beer judging experience, I was assigned to

First of all, your wine making articles are great. One answer I have not seen in your posted articles is whether to stir fining or clearing agents multiply times after adding them in wine. Your

First of all, your wine making articles are great. One answer I have not seen in your posted articles is whether to stir fining or clearing agents multiply times after adding them in wine. Your

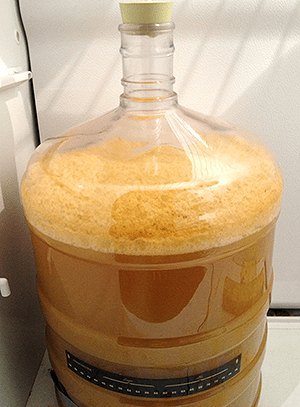

One of the benefits of joining a homebrew club is that you’re often exposed to group events and discounts. My local homebrew club does an annual cider pressing at a local cidery. This year I picked up five gallons of juice. Here’s my game plan for making hard apple cider.

One of the benefits of joining a homebrew club is that you’re often exposed to group events and discounts. My local homebrew club does an annual cider pressing at a local cidery. This year I picked up five gallons of juice. Here’s my game plan for making hard apple cider.