One of the reasons that 1.2 home brewers in the United States have picked up the hobby is that brewing your own beer is a simple, enjoyable pastime that you can do from the comfort of your own home. It’s easy enough for beginners to pick up without much prior knowledge and it’s a great hobby for sharing with friends!

One of the reasons that 1.2 home brewers in the United States have picked up the hobby is that brewing your own beer is a simple, enjoyable pastime that you can do from the comfort of your own home. It’s easy enough for beginners to pick up without much prior knowledge and it’s a great hobby for sharing with friends!

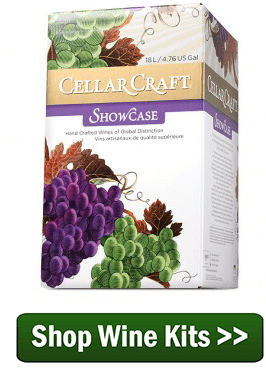

However, if you don’t store your brew supplies and ingredients in the right conditions, you might expose your supplies to mice, spoil the ingredients, or even accidentally have a beer bottle explode! Here’s what you need to know in order to properly store your home brew supplies and ingredients.

Storing Brewing Ingredients

Malted grain and malt extract should be stored between 50-70 degrees. Store malted grains in dry, airtight containers to keep out vermin, and store liquid malt extract in its original can, using the expiration date to judge its timing (once opened, its shelf life will be about three months). Otherwise, your liquid malt extract can be prone to spoilage and contamination.

Hops, meanwhile, should be stored in a freezer to avoid heat, light, and oxygen, while yeast should be stored in the fridge. Hops should be stored within an air-tight container to prevent freezer burn, and they can last up to a year in the freezer.

Yeast can be stored within the manufacturer’s original packaging and according to the manufacturer’s expiration date.

Storage Tips

Storage Tips

Organize your small items (like stirring spoons, racking canes, and brushes) using hooks or a pegboard so that you can easily see and grab what you need. Other small items, like bottle caps and airlocks, fit perfectly in compartmentalized toolboxes.

For larger elements like fermenters, use plastic shelving to create vertical storage. You can also keep unused bottles safe from breaking by storing them in file cabinets.

For dry ingredients that add that little something extra to your beer’s flavor (spices, Irish moss, gypsum, and Burton water salts), make sure to keep them at room temperature in airtight bags. Do not refrigerate your dry ingredients.

The taste of your home brewed beer depends completely on the quality of your ingredients. By storing them safely and according to best practices, you’ll achieve the perfect flavor profile for your original beer. Cheers to home brewing!

—–

About the Author: Kristen Geil is a Digital Content Writer/Blogger at Digital Third Coast, a SEO company in Chicago.

Part 1

Part 1

Part 1

Part 1

Part 1

Part 1