I have been making wine for a number of years and I’ve always had trouble taking hydrometer readings. When using the tube the wine hydrometer came in, the foam on the top of the must or wort and the moisture on the sides causes the hydrometer to stick to the plastic. When that happens, it raises the level of the liquid on the sides of the tube making a hydrometer reading pretty inaccurate. The obvious solution would be to use a larger container but I hate to waste that much material. I’ve tried to make sure the tube is level but the hydrometer always migrates to the side. Any suggestions?

I have been making wine for a number of years and I’ve always had trouble taking hydrometer readings. When using the tube the wine hydrometer came in, the foam on the top of the must or wort and the moisture on the sides causes the hydrometer to stick to the plastic. When that happens, it raises the level of the liquid on the sides of the tube making a hydrometer reading pretty inaccurate. The obvious solution would be to use a larger container but I hate to waste that much material. I’ve tried to make sure the tube is level but the hydrometer always migrates to the side. Any suggestions?

Name: Rick S.

State: Michigan

—–

Hello Rick,

From what you are describing, the plastic storage tube is what’s causing a lot of your problems with taking hydrometer readings. We always recommend to customers that they use something other than the storage tube to take readings. It’s really not what it’s designed to do. Some of them will even leak.

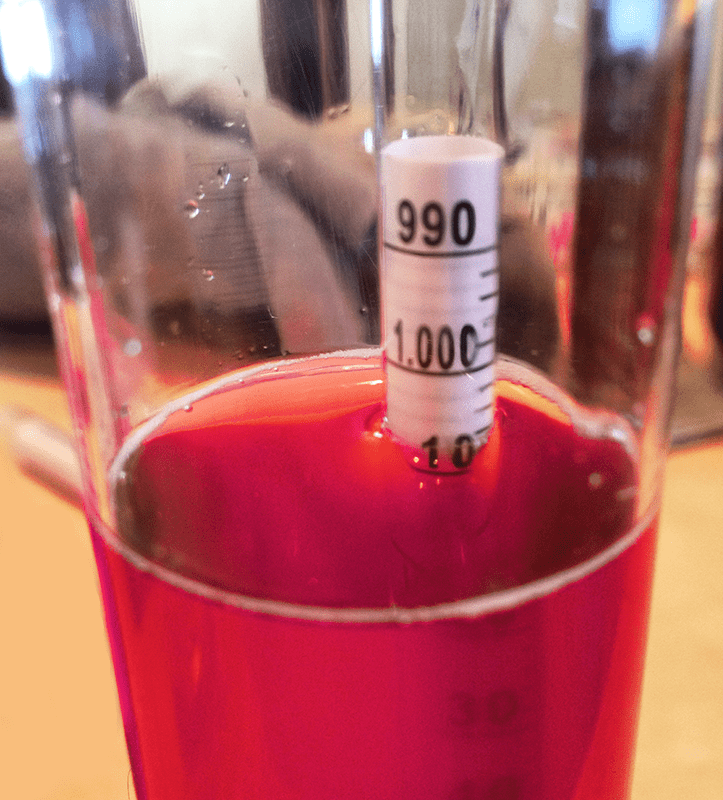

You will be much better off with an actual glass hydrometer jar that is designed specifically for taking hydrometer readings. The diameter of the tube is larger than storage container. The sides are smoother, and the line of sight is clearer. All these things add up to you being able to take hydrometer readings with much more accuracy and less problem.

The glass hydrometer jar can also be quickly sanitized along with the wine hydrometer before taking readings. You can do this by using a sanitizer such as Basic A. By sanitizing your equipment you don’t have to waste any of your wine. Just take the reading and pour the sample wine directly back in the batch. There’s absolutely nothing wrong with doing this.

As for the foaming, there is not much you can do about it. Some of the foam is caused by the natural surface tension of the wine. The agitation causes the bubbles just as if you were pouring a finished wine into a wine glass. Some of the bubbles come from CO2 gas that was made, or is being made, by the fermentation. You can wait a few minutes to see if some of the bubbles settle down enough for you to get a clean reading, but beyond that, I know of nothing practical you can do to rid yourself of all the bubbles.

Also, when you’re taking a hydrometer reading during fermentation, you can have problems with CO2 bubbles clinging to the side of the wine hydrometer. This is when bubbles form from the wine being disturbed and then attach themselves all the way up and down the wine hydrometer.

These bubbles can throw the hydrometer reading off by artificially raising it in the wine sample. One way to avoid this issue is to give the hydrometer a quick spin before taking a reading. This is to dislodge any bubble away from the hydrometer.

One other thing I would like to point out is that when you are actually taking the hydrometer reading, you would like you eye to be level with the surface of the wine in the hydrometer jar. This will allow you to obtain the most accurate reading. If you are taking your hydrometer reading from an upward angle, the surface tension of the wine will cause it to curve a little against the hydrometer, giving a bit of an optical illusion.

One other thing I would like to point out is that when you are actually taking the hydrometer reading, you would like you eye to be level with the surface of the wine in the hydrometer jar. This will allow you to obtain the most accurate reading. If you are taking your hydrometer reading from an upward angle, the surface tension of the wine will cause it to curve a little against the hydrometer, giving a bit of an optical illusion.

Rick, I hope this information about taking hydrometer readings helps you out. It’s just a few of the things I’ve learned along the way while taking my own readings.

Happy Wine Making,

Ed Kraus

—–

Ed Kraus is a 3rd generation home brewer/winemaker and has been an owner of E. C. Kraus since 1999. He has been helping individuals make better wine and beer for over 25 years.