I have 3 five-gallon carboys of zinfandel with a low pH of 3.00, and what I identify as too much tannin. The wine has been “aging” for 18 mos. now and still unacceptable by my taste. Is it too late to doctor it to lower the tannin? It has been stored cool (I’m in N. California) and I can’t heat it. Too late for treating with egg whites or bentonite?

I have 3 five-gallon carboys of zinfandel with a low pH of 3.00, and what I identify as too much tannin. The wine has been “aging” for 18 mos. now and still unacceptable by my taste. Is it too late to doctor it to lower the tannin? It has been stored cool (I’m in N. California) and I can’t heat it. Too late for treating with egg whites or bentonite?

Name: Tony S.

State: CA

—–

Hello Tony,

I see your wine is still a beautiful, young color, even after 18 months. That is probably partially due to the fact that it has such a low pH. This can help to keep a color fresh looking as well as keep any potential spoilage in check. The bad part is as you have stated, it doesn’t taste good. That is the primary issue when you have to much tannin in any wine.

You said that you tested the pH of your wine and thought it was too low because of too much tannin being in the wine as opposed to the other typical reason, which is having too much tartaric acid in the wine. This could be easily verified by testing the wine with an acid test kit. This would tell you very precisely if there was too much tartaric acid in the wine or not.

If you do not want to do this you can go by taste and experience, but this can only tell you what direction to take in solving this problem, not necessarily how sever it is. If there is too much tannin in this wine you would expect it to taste bitter and dry-puckering. If it is a tartaric acid problem you would expect a tart and sharp flavor.

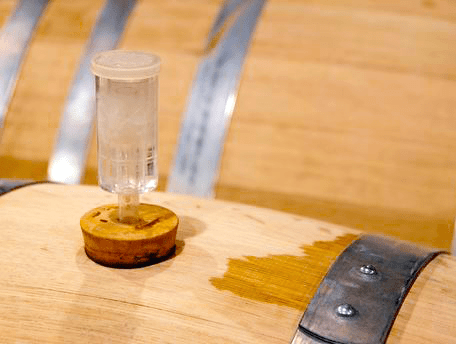

If you do have too much tannin in the wine, just as you implied, bringing the temperature up would most likely drop some of it out. I would not hesitate to use artificial means of heat on the wine to heat stabilize the wine. Bring the wine up to about 80°F. for about a 3 days. Because the wine’s pH is so low oxidation will not be an issue.

You can use something as simple as an electric blanket it to warm it up. We also have a heating belt that can warm five gallons by about 20°F. Just be sure to use a thermometer of some type to monitor just how hot the wine is getting.

Once the wine has reach 80°F. (this could take a day or two) treat is with bentonite and let the wine sit for the rest of the week.

If you are dealing with too much tannin in your wine, you will notice a remarkable change in the wine after doing this. You may want to test the pH again. If you do not notice any change, then I doubt you are dealing with a tannin problem and urge you to test the wine again with an acid testing kit. More than likely you will need to use acid reducing crystals on the wine.

Beyond this, if you do see improvement in the pH, it is possible to treat the wine a second time with bentonite, if you deem it necessary, but I would not heat it a second time. Once the pH rises above 3.2, you do need to be a little more cautions about oxidation. You will typically receive marginal improvement from a second treatment in such a potentially severe case.

Hope this information helps you out.

Best Wishes,

Ed Kraus

—–

Ed Kraus is a 3rd generation home brewer/winemaker and has been an owner of E. C. Kraus since 1999. He has been helping individuals make better wine and beer for over 25 years.

One of the long, ongoing discussions in the world of home wine making is, “should I be bulk aging or bottling aging my wines?” While bottle aging wine has its merits, there are some good reasons to consider bulk aging. Here’s some food for thought when considering bulk aging vs bottling aging your wine.

One of the long, ongoing discussions in the world of home wine making is, “should I be bulk aging or bottling aging my wines?” While bottle aging wine has its merits, there are some good reasons to consider bulk aging. Here’s some food for thought when considering bulk aging vs bottling aging your wine.