Finally – one of my favorite parts of homebrewing! It’s time to package the Steam Freak Special Bitter. I will be kegging this homebrew with priming sugar.

Finally – one of my favorite parts of homebrewing! It’s time to package the Steam Freak Special Bitter. I will be kegging this homebrew with priming sugar.

After about ten days in the secondary fermenter, it’s time to move the beer to the keg. I enjoy this stage because you can finally start to taste what the finished beer will be like. I decided to keg this batch so I can take it on a camping trip in a couple weeks. Because I like to experiment, I also thought I’d try kegging this homebrew with priming sugar. This is essentially what British brewers do when they make “real ale,” or cask conditioned ale. Instead of forcing CO2 into the beer from a CO2 tank, carbonation is created by the yeast in the beer, which is given a small dose of priming sugar when it goes into a keg. Makes sense for an English special bitter, right?

Even though I primed the keg, the keg filling procedures are very similar to kegging procedures you would do otherwise.

- Clean the keg.

If you did a good job rinsing the last batch, this should be easy. A quick soak in One Step should get the job done. Turn the keg upside down to get the top. For a dirtier keg, or if you haven’t disassembled it in a while, take the keg apart and give all of the dip tubes and posts a good scrub inside and out. Be sure to run the clean solution through your picnic tap, too. - Sanitize the keg.

Basically repeat the procedures above with a sanitizing solution. Fill the keg with water and soak for a few minutes in a Star San or Iodophor solution. Turn the keg upside down to get all parts. Run the solution through your picnic tap. Drain and allow to dry. Reserve some of the solution to soak the lid.  Check for leaks.

Check for leaks.

Once the keg is sanitized, fill the keg with CO2, just 5-10 psi. Check for leaks by spraying soapy water around each of the fittings. Apply keg lube or replace o-rings as needed to seal leaks.- Vent the keg and refill with CO2 3-4 times.

This will purge air from the keg and fill it with carbon dioxide, which will help prevent your beer from going stale. - Prepare a priming sugar solution just like you would for bottling, but use about half the sugar.

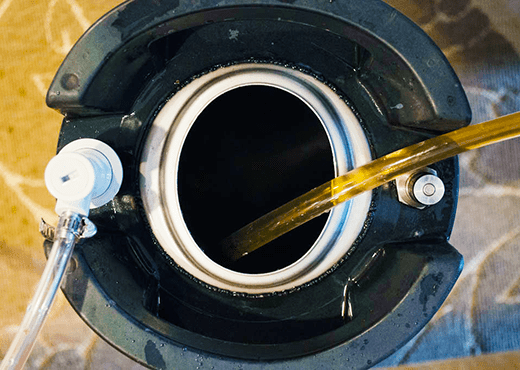

Mix about 2.5 oz. of priming sugar with two cups of water. Boil for about 15-20 minutes. Cool, and then pour into your sanitized keg. If you want to force carbonate the beer, then skip this step. - Siphon the beer into the keg.

Siphon the beer from the fermenter into the keg. The priming sugar should mix well as the beer flows in. Close the keg and apply just enough pressure to get a good seal. - Wait.

Just like with bottling conditioning, when kegging your homebrew with priming sugar your need to set the keg in a room at about 70˚F and give it about two weeks to carbonate. - Chill keg, check carbonation and serve.

Chill the keg to serving temperature. For an English bitter, this will be about 50˚F. Give the yeast in the keg a little time to settle. Take a sample of beer. (Your first pour or two will likely have some yeast sediment.) How’s the carbonation? Too much? Vent the keg to release some pressure. Too little? Give the keg a little more time to condition or add a little CO2 pressure from your tank. Without a hand pump, you’ll need CO2 pressure to serve the beer from the keg. Just 5-10 psi should do it!

Kegging your homebrew with priming sugar is a natural way of preparing it. Also realize that you can force carbonate your keg as well. Each has it’s merits.

Curious how the Steam Freak Special Bitter turns out? Stay tuned for a tasting!

Read the other posts of this review! Part 1 | Part 2 | Part 3 | Part 4 | Part 5 |

—————————————————————————————————————–

David Ackley is a beer writer, brewer, and self-described “craft beer crusader.” He holds a General Certificate in Brewing from the Institute of Brewing and Distilling and is founder of the Local Beer Blog.