The BeerSmith blog featured a video interview back in 2015 that had some very good insights to making mead. It was with the founder of Moonlight Meadery, Michael Fairbrother, how to brew your own mead. As I’m planning on making my first mead, I thought I’d share some of the mead making tips I learned from the video.

The BeerSmith blog featured a video interview back in 2015 that had some very good insights to making mead. It was with the founder of Moonlight Meadery, Michael Fairbrother, how to brew your own mead. As I’m planning on making my first mead, I thought I’d share some of the mead making tips I learned from the video.

Below are some of Michael’s key mead making tips. There’s enough clear-cut information here that you will be able to create your own mead recipe:

Water

- Use clean, filtered, or reverse osmosis water for your mead.

Honey

- Use fresh, non-pasteurized honey whenever possible for best flavor. See the honey locator at honey.com to find fresh, raw honey near you!

- Different honeys have different flavors: tupelo honey tends to be spicy, and citrus honey might have notes of orange.

- Michael recommends using cranberry, blueberry, blackberry, and avocado honeys, among others.

- Michael does not recommend buckwheat or heather honey, as these tend to be heavy.

- Michael suggests a honey to water ratio of 25:75 for a semi-sweet mead. Use more honey for a sweeter mead, less honey for a drier mead.

Yeast

- One of Michaels biggest mead making tips is do not use champagne yeast.

- Michael uses Lalvin 71B wine yeast for all of his meads.

- Pitch about 1 gram of yeast per gallon for a healthy fermentation.

Equipment

If you’re a homebrewer or winemaker, you probably already have all the equipment you need for making mead.

- Use a fermenting bucket for primary fermentation. It’s easier to stir the must and helps prevent some kind of blow-off situation.

- After primary fermentation, move the mead to a carboy and minimize headspace.

Yeast Nutrients

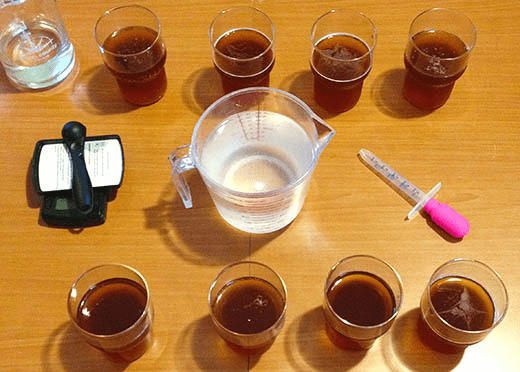

- Always rehydrate your yeast nutrient in a pint of water.

- For best results, divide your yeast nutrient by four and pitch it four times during primary fermentation: at 0, 24, 48, and 72 hrs into fermentation. This will help the mead develop more quickly.

Fermentation

- Primary fermentation – Michael usually lets his mead sit for three months before racking to a secondary fermenter.

- Ferment at about 62°F. This is one of Fairbrother’s favorite mead making tips. The cooler temperature will result in a longer fermentation, but with a cleaner tasting mead.

- Michael recommends using bentonite or a wine filter to get good clarity.

- Sulfites or sorbates can be used to keep the mead stable after fermentation.

- Flavorings – Moonlight’s most popular mead is made with apple, honey, cinnamon, and vanilla.

- Fruit – Adding fruit to a mead makes a melomel. The fruit is typically added right at the beginning, though it can be added to the secondary as well.

- Spices – Add spices to your mead to make a metheglin. Add the spices during secondary fermentation. Taste the mead throughout the secondary fermentation and rack the mead to another fermenter when the balance tastes right. This may be just a few days for some of the more aggressive spices.

Resources

Resources

These are great mead making tips for the beginner. You can also fine more information in the book Mead Making, available in the E. C. Kraus web store.

Are you a fan of making mead? What kinds of honey do you use, and what is your favorite style of mead to make? Do you have any mead making tips? Or, maybe a mead recipe you’d like to share?

—–

David Ackley is a beer writer, brewer, and self-described “craft beer crusader.” He holds a General Certificate in Brewing from the Institute of Brewing and Distilling and is founder and editor of the Local Beer Blog.