Can you give me any information on how barometric pressure would affect the fluid level in an air lock. Some days they show negative pressure and a day or two later they are making bubbles again. I can’t tell if fermentation is done or not.

Can you give me any information on how barometric pressure would affect the fluid level in an air lock. Some days they show negative pressure and a day or two later they are making bubbles again. I can’t tell if fermentation is done or not.

Thank you

Jerry

—–

Hello Jerry,

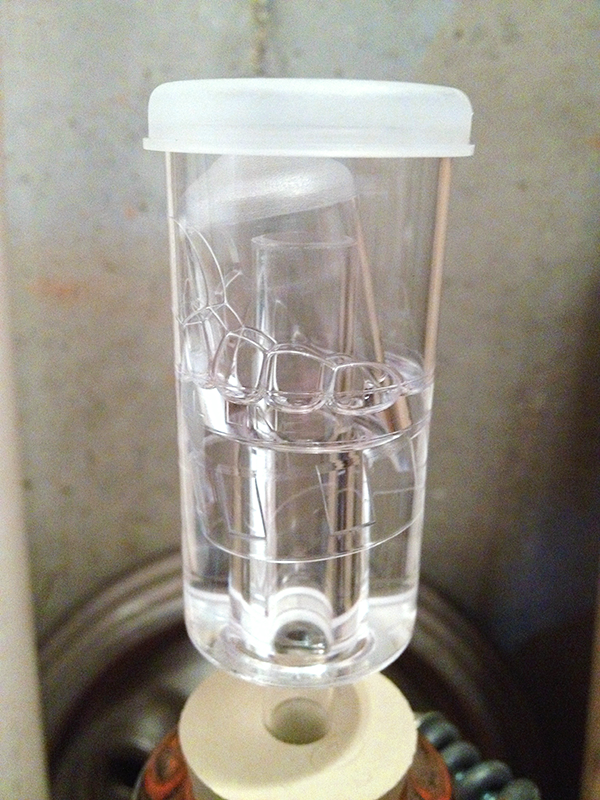

An air-lock is what seals the outside world from your wine during and after fermentation. It is a barrier that allows gases from the fermentation to escape while keeping little bugs and other intruders out.

You attach an air-lock to a fermenter with a rubber stopper. The stopper has been drilled with a hole into which the air-lock is inserted. These rubber stoppers can be purchased in many sizes, therefor you are able to use the air-lock on anything from a gallon glass carboy to a huge plastic fermenter.

The air-lock is filled half way with water. This is what actually creates the environmental barrier. As the fermentation creates gases inside the fermenter, the pressure rises and the gases escape by bubbling through the water in the air-lock.

Bubbles or air going backwards in an air-lock can be caused by a couple of things:

As you mentioned already, barometric pressure can play some role in this. If the barometric pressure increases you could notice a slight backwards movement or pressure on the water, but this would be nothing significant. It would not be enough to create more, than say, one bubble going backwards.

What is most likely causing the air-lock to bubble backwards is a temperature change of the wine. As a wine cools down it contracts or shrinks – much more so than the glass or plastic of the fermentation vessel.

Contracting wine sitting in glass jugs or even a plastic fermenter would cause a vacuum to occur in the head-space. This would cause reverse bubbling action within the air-lock, or a sucking in of air. Then as the wine warms back up you would see bubbles going through the air-lock in the right directions. This would make the wine appear as if it were slightly fermenting again, regardless if it was or not.

Contracting wine sitting in glass jugs or even a plastic fermenter would cause a vacuum to occur in the head-space. This would cause reverse bubbling action within the air-lock, or a sucking in of air. Then as the wine warms back up you would see bubbles going through the air-lock in the right directions. This would make the wine appear as if it were slightly fermenting again, regardless if it was or not.

Your best defense against having an air-lock bubble backwards is to keep the fermentation temperature stable. This will give you a more healthy fermentation, as well. Yeast like to ferment at a steady 70° to 75°F.

Happy Wine Making

Hello Jerry…really using a Hydrometer would probably be your best bet. You can never rely on airlocks to predict fermentation in your wines for a solid reading. Make sure that your SSG reading is the same 2 days in a row with NO bubbles. An airlock will not tell you that. Happy Winemaking!!

My air locks don’t appear to be working at all. There are no air bubbles showing in the sterilizer I have in my air lock, not after I racked it into the first carboy from the fermenting pail and not from the carboy after racking a second time and proceeding with the degassing process. The degassing process is now into day two, stirring about every 30 minutes and still very foamy. Yet no air bubbles when air lock is in place. This is a Reserve du Chateau kit. Any advice?

Bubbling through the air-lock can stop as soon as 5 days or take as long as 15. What really matters is that the fermentation is actually complete when the bubbling does stop. What I mean by this is that all the sugars in the wine must have been converted into alcohol. The only way to determine this is by taking a reading with a wine hydrometer. Having said this, it does not sound like you have a problem, but I would check the wine with a hydrometer anyway… it’s just a good habit to get into.

Thanks so much for the information. I am so enthused about making wine that I absorb all information gladly.

thanks for the posting really a good source of info

I am making pepper mash had this happen with some Pickle Pipes and I kinda flipped out. Thanks for letting me know the name of the process. I have some caps that are inverted where they normally bubble outward. There’s no mold or anything else that I can detect through the mason jars I’m using. Think everything’s ok in there?

Matthew, without being there, we really cannot say for sure that everything is fine. However, if you are not seeing anything growing in the mash it is probably fine. I would recommend try to move it to a place where the temperature is more stable to avoid any future problems.

I like using the S-lock airlocks because you can always tell if there is CO2 pressure in the fermenter. However, there is one time we did have all the airlocks work in reverse. I had about 20 starters going, and 4-5 wines and beer. We had what I think was called a haboob at the time in Wisconsin. Weather was fine, then all of a sudden we heard this roaring sound. We went outside to see what it was, and a huge wind gust had passed by, picking up a barrel of traction sand at the bottom of the hill and throwing it all in our faces and everywhere else. It roared down the street, taking all our plants off our dock with it. When we went back inside, we found all of our s-locks had been sucked back into the fermenters and were dry. A rare occurrence, yes, but for that reason I tell all of our customers to make sure they put sanitizer or vodka in their airlocks, and to make sure you empty the airlocks of bugs every once in a while if they seem to be getting a lot of bugs in them. Luckily, none of the wines were adversely affected.

Good information, thank you for sharing.. I have experienced this issue once in the last five years and it was due to a rather drastic change in temperature when left the door to my wine room open.

Could anyone advise me … while installing the airlock, some of the sodium metabisulphite solution inside of it dripped back into the juice/yeast mixture in my primary fermentation pail. The yeast had just been sprinkled atop the juice when this happened … I’m hoping this doesn’t kill the yeast…any thoughts on this?

Any info is greatly appreciated 😉