To answer the question: what is beer yeast? We must first back up and discuss what yeast is, in general. Yeast is the single-celled micro-organism responsible for turning sugar into alcohol. Yeast can be found almost anywhere, in the air, hanging out on fruit, even in this guy’s beard. Without yeast, there would be no beer! Even though yeast’s role in fermentation wasn’t discovered until the 1800s, brewers have been unknowingly using it to make beer for thousands of years.

To answer the question: what is beer yeast? We must first back up and discuss what yeast is, in general. Yeast is the single-celled micro-organism responsible for turning sugar into alcohol. Yeast can be found almost anywhere, in the air, hanging out on fruit, even in this guy’s beard. Without yeast, there would be no beer! Even though yeast’s role in fermentation wasn’t discovered until the 1800s, brewers have been unknowingly using it to make beer for thousands of years.

There are hundreds of different kinds of yeasts, but when it comes to brewing beer, we’re interested in one in particular: Saccharomyces cerevisiae. Strains of Saccharomyces cerevisiae, commonly referred to as brewer’s yeast or beer yeast, are further divided into two broad categories:

- Ale yeast – a top fermenting beer yeast, performing best between 55°-70°F, ferments fairly quickly

- Lager yeast – a bottom fermenting beer yeast, performs best around 45°-50°F, takes longer to ferment

(Top vs. bottom fermenting refers to where in the fermentation vessel the beer yeast is most active.)

Within each of these two categories are many beer yeast strains that produce flavor characteristics that define a particular style of beer. One of the strongest examples of this is in Bavarian wheat beers. The banana and clove character in hefeweizens comes from the yeast!

The Role of Beer Yeast in Fermentation

In brewing, there are four stages in the fermentation process:

Pitching > Respiration (lag phase) > Fermentation > Settling

In the first step, healthy, viable yeast cells are added to the wort. Next, in the respiration phase, yeast consumes dissolved oxygen in order to grow and multiply. The goal is to have a large colony of yeast cells so that they can quickly and effectively ferment your beer. (This is why you aerate your beer prior to pitching yeast.) Next comes the fermentation step. At this point, the yeast cells consume sugar and produce alcohol and carbon dioxide. Finally, when the fermentation is complete, the yeast cells settle out to the bottom of the fermentation vessel.

Liquid vs. Dry Yeast

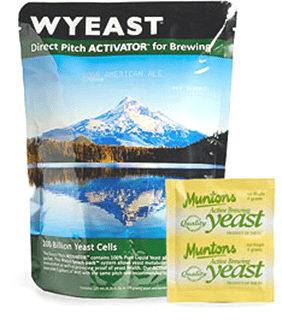

Homebrewers have a few choices to make when selecting a beer yeast strain for their brew. Beer yeasts are available in both liquid and dry form. Dry beer yeast packets are easy to use, easy to store, relatively inexpensive and contain lots of viable cells. Many homebrewers recommend that dry yeasts be rehydrated prior to pitching; some don’t think this is necessary. Popular dry yeast producers include:

Liquid beer yeast have their own benefits. For one, they don’t need to be rehydrated, saving some time on brew day. The other benefit is that there is a greater variety of liquid yeasts than dry. The main drawback is that liquid beer yeasts tend to cost a little more than dry yeasts, but many homebrewers swear that liquid yeast cultures make better beer.

When picking a beer yeast, consider the following: First, are you brewing an ale or a lager? What style of beer are you brewing, and what strain is best for that style? Finally, would you rather use liquid or dry yeast?

In the future we’ll try to come up with a clearer answer to the question: what is beer yeast? But for now, happy brewing!

What’s your favorite homebrewing yeast strain? Share in the comments!

———————————–

David Ackley is a beer writer, brewer, and self-described “craft beer crusader.” He holds a General Certificate in Brewing from the Institute of Brewing and Distilling and is founder of the Local Beer Blog.

that was very informative. Thanks.

I plan on using a liquid yeast next time around – just 4 an experiment.

I have no issue with dry yeast – as long as I make starter B4 adding it to the must. This allows me to determine it viability on the front end.

What makes the difference between beer and wine?

Zephrine, it is important to understand the beer yeast and wine yeast are different in the way they ferment. Most beer yeast will only ferment readily up to 8% or 9% while wine yeast routinely ferment up to 14%. Beyond this import fact is that these yeast produce very different enzymes while fermenting. The result is the production of very different flavors.